MARTIN AUDIO AND LINE ARRAY TECHNOLOGY

By Jason Baird

Back in 2002 Martin Audio launched the world's first three-way, all-horn-loaded line array; the Wavefront W8L. At that point in time and largely still to this day, line array systems were driven with the same input signal to each cabinet, with directivity adjusted by splay angles alone.

W8L broke that mould, using a technique we named 'band zoning', where the array was divided up in to short, medium and long throw sections. The state of the art for DSP processing at the time (the XTA DP226) gave us six output channels to use for each array. Measurement and experimentation showed us that the best results were obtained using one channel for the LF of the whole array, two channels for the mids (short and medium/long throw) and three channels for the HF, mapped to short, medium and long throw respectively.

The goal was to take the results of what could be called a 'classic' line array and further improve the front to back consistency in the audience region. Typically the front was always too loud and bright and the back seats 200-300ft away lacked HF clarity. Being able to EQ the front/short throw section independently cured the first problem but it took an understanding of 'air excess attenuation' for us to get a handle on how to overcome the lack of projection to the back of the audience.

The phenomenon of 'air excess attenuation' dictates that the water vapour in the atmosphere will cause attenuation of higher frequencies far more than lower ones, as sound waves propagate through the air. It is also a linear phenomenon, in that for any given frequency the attenuation is X many dB per unit distance, as opposed to the inverse square law.

The relationship between air excess attenuation, air temperature, humidity and pressure is complex but well-documented, which meant that we could calculate for it and thereby appropriately EQ the long throw part of the array in order to preserve HF balance over distance. As changes in atmospheric conditions could change the attenuation at 8kHz over a propagation distance of 300ft by 10dB or more, this is an important factor to take in to account.

This led us to start building acoustic models of line arrays, which modelled the output of the system. They took in to account splay angles, the band zoning EQ and the effect of air excess attenuation on the output of each individual source in the array. The insight this gave us was invaluable and it told us two things which hitherto have defined and directed Martin Audio's line array technology offering.

The first being if we split the array up in to even more processing zones, we'd get more consistent results. The second was that our models were consistently 'out' in that they tracked measured data but always differed in what turned out to be a highly consistent manner. So we were missing something but what was it?

When developing the O-Line micro line array in 2005, we were determined to find out what was wrong with our acoustic model. To do so we turned to what at the time was largely an academic analysis technique, called the Boundary Element Method (BEM). This allowed us to model the directivity of an acoustic source as well as the effect of its cabinet and more importantly, the other physical objects around it, such as the neighbouring speakers in the line array.

We found that the simple physical presence of neighbouring speakers in a line array, had a massive effect on each speaker's output characteristics and that this was slightly different for each position in the array. This was the missing piece of the jigsaw, which allowed us to correct our model and track measured results to within an average window of +/- 1dB.

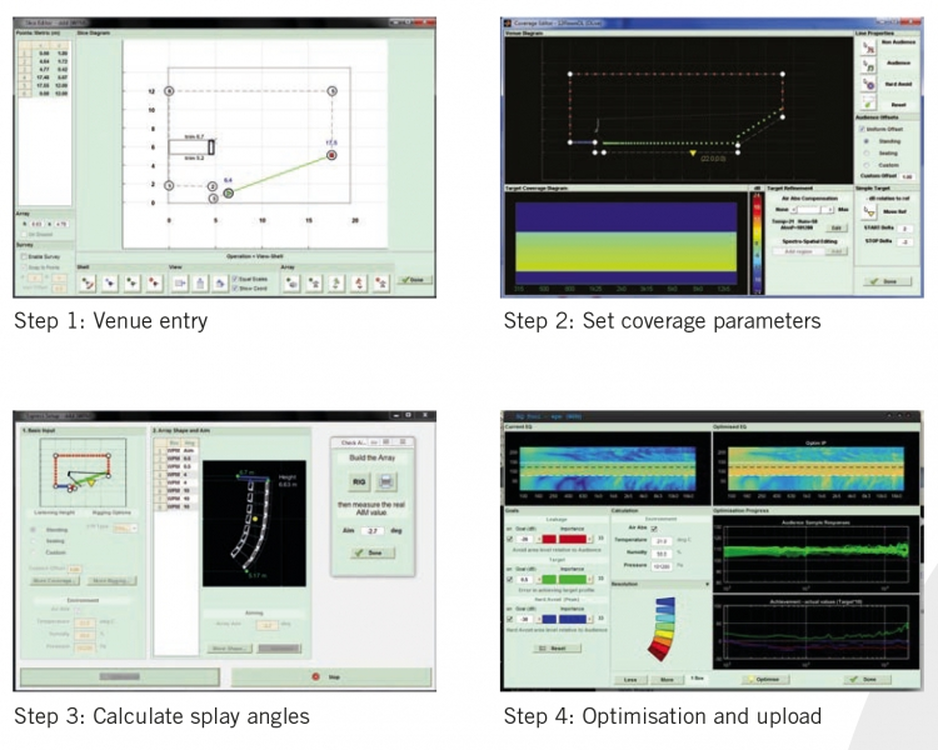

Now we could produce our own proprietary software, which allowed users to accurately model the output of the O-Line system. However, this led us to consider what else we could do to further automate the array design process, could we get the computer to help?

We realised that if our computer model was accurate to within +/- 1dB, we could get the computer to change aspects of the array design (with O-Line we started with splay angles), then recompute the result and compare it with a goal, such as frequency response flatness from the front to the back of the required coverage area.

Taking this idea to the extreme we applied mathematical numeric optimisation algorithms to search for the best array shape in order to meet a particular goal. So now we were getting the computer to design array deployments for us and crucially, it was getting it right and doing far better than we could by trial and error.

This was a major step but the big leap forward came when we created our flagship touring system, MLA. Here we returned to the idea of optimising the DSP processing for each individual acoustic cell in the array, which we'd touched on with W8L but didn't have the DSP power or the modelling capability to action at that time.

MLA retained W8L's three-way, all-horn-loaded principle but in a more modern, smaller and lighter package, even though it has six channels of Class D amplification and DSP on board (one for each cell), plus a high speed control and monitoring network.

Allowing the computer to have a free hand to optimise not only splay angles but the FIR-based DSP processing of each acoustic cell yielded results way beyond our expectations. The ability of FIR filters to manipulate magnitude and phase of the audio signal independently of each other was a key component of how this was being achieved.

Now we were achieving startlingly consistent frequency responses from front to back of the audience as well as being able to control SPL profile, simply by entering target values in to our optimisation software, Display. But there was more.

MLA had an uncanny ability to attenuate output directly underneath it and also beyond the extent of the coverage pattern. This feature was developed in to what we termed 'hard avoid', where the user could program a specific part of the venue in to Display, where sound levels needed to be minimised.

The results were startling. Suddenly the stage was quiet, or a massive reflection off a back wall was gone, or perhaps most pertinently for outdoor events, the noise spillage beyond the back of the crowd was significantly reduced. Now we had a system which was doing things that others could not and we had these factors under computer control. The accuracy of the computer model meant what you saw on screen was what you measured.

Moving to the present day, we recognised that MLA and its smaller brothers are flagship systems. As such we wanted to bring many aspects of their performance to a wider market and so the Wavefront Precision line arrays were borne.

Wavefront Precision allows scalable resolution of DSP processing and amplifier channel count. Display optimises the FIR filters just as it did for MLA but now the user can choose how many blocks the array is split in to, with the amplification and filtering provided by our iKON amplifiers.

In the case of the smaller of the two new products, WPM, the user can choose from 1 to 4 box resolution and in the case of the medium format WPC, 1 to 3 boxes. As resolution increases, so does coverage consistency, though even at the coarsest resolution the results are significantly better than a classic same-signal-to-each-box line array system, driven by an off the shelf factory preset.

In contrast, the competitive landscape has largely remained the same in terms of how arrays are driven, as it was back when the modern line array emerged in the 1990's. As such the market has focused on maximising output vs size as well as speed of deployment, whilst remaining conscious of diminishing production budgets.

In developing the Wavefront Precision range, our goal was to deliver these generic performance requirements, whilst adding more than a little bit of the magic of our MLA series…at a compelling price point.

Jason Baird, R&D Director

May 2017